Environmental Sustainability Policy

Company Statement

Tam Hangers are one of the largest garment hanger providers to EU retail, with a truly international footprint as our products and services reach garment manufacturing regions across the world. We recognise, and drive opportunity to positively impact standards throughout our supply chain by applying 4 key pillars to our standard operating procedures.

We work with various third parties to evaluate and monitor our progress via various industry standards such as IS14001, SEDEX, SOCAM and GRS. Our Re-use programme has been certified by the Carbon Trust and its proven that the closed loop re-use programme uses 79% less carbon than producing a new hanger.

The sustainability understanding of Tam Hangers is based on the principle of continuous improvement. We effectively define and address sustainability risks and opportunities. We act with the awareness that the development is not only economic development. For Tam Hangers, sustainability is not a choice but a responsibility.

Our sustainability goal; While creating value for our country and our global customers, it is to act without consuming the future, and even to leave more opportunities for future generations.

Under the heading of sustainability to achieve these goals; We adopt the following policies and proceed in this way:

- Environmental Policy

- Energy Savıng And Effıency Polıcy

- Waste Management Policy

- Occupational Health & Safety Policy

- Human Rights Policy

- Social Responsibility Policy

- Quality Policy

At Tam Hangers, it is an integral part of our business that for sustainable development and a clear future, we take the necessary measures to minimize any negative impacts as a result of our activities. In this regard, by applying "Environmental Management System", our system is revised periodically according to changing conditions and we are continuously trying to increase our environmental performance.

- We follow the compliance of all laws and regulations relating to the environment.

- Taking into account the environmental effects during our production, we try to prevent pollution at the source.

- Activities that occur during our solid, liquid and gas waste, our mitigation measures are taken into account and efforts are implemented to re-use or recycle.

- Any accident or emergency that may occur during our activities, to minimize environmental damage, are planned and applied at all levels.

- All of our employees are aware of the environment to achieve success and are subject to training to give individual responsibility.

- We try to minimize the amount of consumption by using natural resources efficiently. To this end, the whole process of planning and development of an environmentally friendly approach system is revised continuously during its implementation.

- With national and local government agencies, and in cooperation with other industry organizations and suppliers, we are working together to raise our environmental standards.

All of our employees are working very hard to achieve the objectives of this policy. Each unit is responsible for making the necessary studies regarding its operations and implementations.

We actively remove virgin material from our supply chain buy utilising recycled materials wherever possible.

- All our black hangers produced contain over 90% recycled material.

- Instead of incandescent filament lamps, LED and energy saving bulbs are used and energy saving is achieved by using sensor lamps generally.

- In the offices, natural gas is used instead of air conditioning for heating.

- Compressor air is taken from the outdoor environment. This saves energy by reducing the air temperature.

- By using wind energy in cooling towers, the energy required for cooling is saved.

We continue to work on our targets such as providing the energy required for lighting with solar energy.

Our sensitivity to energy saving and efficiency will continue to increase with the help of these studies and other studies that we plan to do.

PREVENTION: We strive to identify methods by focusing on production processes will not cause waste.

REDUCTION: It aims to reduce the amount of wastes generated at the source and reduce unnecessary consumption.

Some applications that we have made with this awareness are as follows:

- When purchasing electrical devices, efficiency and compliance with standards are strictly observed and, if possible, devices with energy class A + and higher are selected.

- Instead of incandescent filament lamps, LED and energy saving bulbs are used and energy saving is achieved by using sensor lamps generally.

- Unused power tools are kept closed. The lights are switched off when leaving the office or at work. The air conditioners and computers are turned off when not in use. However, the pneumatic machines are de-aired when not in use. Unnecessary use of compressed air is prevented.

- The electric motors used in the factory are selected from high efficiency motors. Inverter is used especially in electric motors operating at variable load.

- In the offices, natural gas is used instead of air conditioning for heating.

- We use heat insulation jackets to save energy in most injection molding machines.

- Compressor air is taken from the outdoor environment. This saves energy by reducing the air temperature.

- In order to prevent water wastage, water reducing nozzles are installed in the faucets. Thus, the waste of water is prevented.

- By using wind energy in cooling towers, the energy required for cooling is saved.

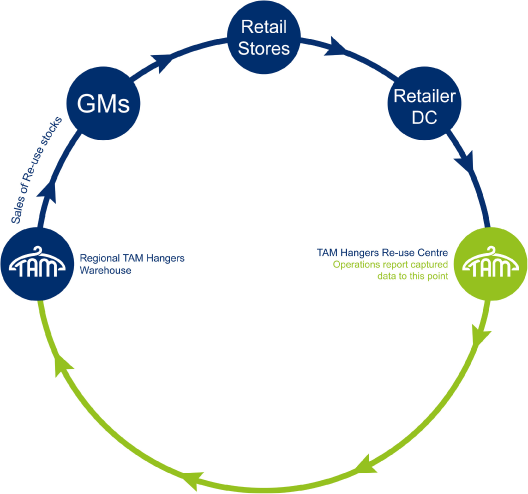

We’re passionate about green, cost-effective service. That’s why we created the Re-Use program: the first ever closed loop hanger solution.

We work with various third parties to evaluate and monitor our progress via various industry standards such as IS14001, SEDEX, SOCAM and GRS. Our Re-use programme has been certified by the Carbon Trust and its proven that the closed loop re-use programme uses 79% less carbon than producing a new hanger.

We partner with major retailers and garment manufacturers to re-use hangers - dramatically reducing the number that end up in landfill, and the cost to clients.

Hangers in the Re-use program are recycled at the end of their lifecycle and recycled plastic used in producing new hangers to prevent plastic from ending up in landfill.

We currently have the largest hanger production facility in Europe which practises lean manufacturing techniques minimising waste and improving efficiency.

Waste management is carried out under the supervision of "Provincial Directorate of Environment and Urbanization". Waste are collected separately at source and collected in temporary storage areas. Then it is sent to licensed companies. Training and studies are ongoing for less waste generation.

DISPOSAL: Waste that cannot be recovered or recycled, fall within the scope of the zero waste project: all wastes are given to licensed companies to contribute to various recycling stages or their disposal in a manner that minimizes environmental damage.

At Tam Hangers we pride ourselves on our recycling and waste management.

Some of our achievements include:

- Managing our own waste stream.

- Less than 1% into general waste.

- Card sorted and reprocessed at our recycling partner.

- Steel sorted and reprocessed at our recycling partner.

- Plastic polymers processed on site and moved on to our compounding partner.

- PS and PP polymers are reused in a circular economy in producing virgin products.